What has changed?

AvtoVAZ has modernized the production of its flagship model, as reported by «Auto News of the Day».

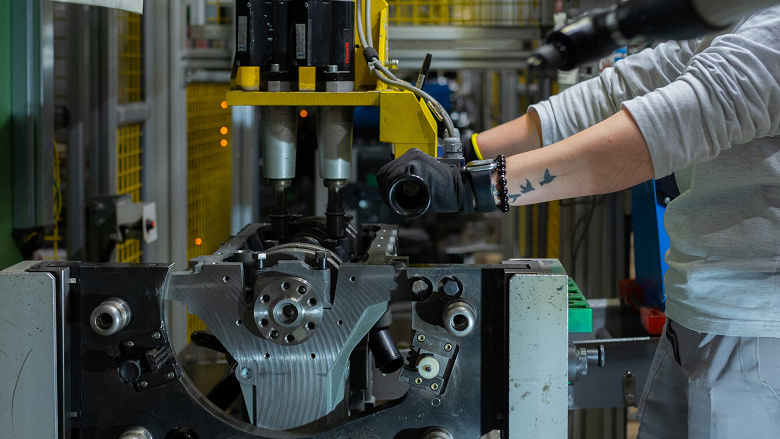

We are talking about automation of work processes in the power unit assembly shop for Lada Vesta. The plant said that modernization of the line of the engine collection area and optimization of their «repacking» allowed to improve working conditions. If we estimate the time period per year, then this improvement will allow AvtoVAZ to save about 6 million rubles.

«Optimized engine repacking. The operator immediately loads the internal combustion engine directly onto the collection cart, and then the engine goes for assembly. A lot of work has been done. We replaced and manufactured a new line, launched live carts and made assembly tables for them, on which the entire assembly is carried out», — said the head of the assembly and installation of power units Denis Shilkin.

As a result of the modernization, some employees were freed up, who were sent to install a new automatic transmission, and the engine assembly process became more convenient thanks to the introduction of rotary tables.

«If the engine was running on the old line, it could not be turned over. Now the operator can press the lever at any time, turn the engine over», — explained Denis Shilkin.

AvtoVAZ continues to improve production, currently setting up the Pick to light system, which allows the assembler to create kit kits without errors.