The new 3D printer will be able to print products up to two meters in diameter and weighing up to half a ton

At the Rostec enterprise NIID (Research Institute of Technology and Organization of Engine Production) a workshop has been created for 3D printing of parts for the promising PD-35 aircraft engine. Domestic equipment will make it possible to produce parts up to two meters in diameter, one meter in height and weighing up to half a ton. Previously, such products could not be made in the form of a single part and were assembled from several elements.

For example, the robotic installation ILIST-XL is used to produce parts from heat-resistant nickel and titanium alloys using direct laser growth technology. This equipment was developed and produced by the Institute of Laser and Welding Technologies of the St. Petersburg State Marine Technical University. And for the production of large-sized workpieces measuring more than a meter in diameter, a hybrid complex is designed, which is equipped with two types of equipment at once — laser machine and five-axis milling machine.

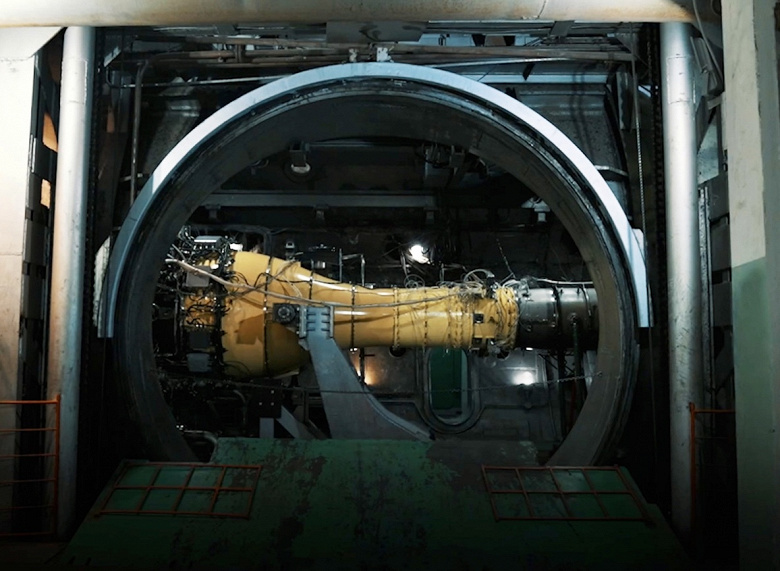

Recall that the PD-35 should become the largest Russian aircraft engine; it is planned to be used on a promising long-range aircraft (modernized Il-96) and a large military transport An-124-100 «Ruslan» . The production version of the PD-35 will most likely appear no earlier than 2030. At the end of last year, the governor of the Perm region, Dmitry Makhonin, reported that a prototype of the new aircraft engine was already being assembled.