Technology developed by Tokyo Electron

Hynix is testing a new technology that it may use in the near future for the production of flash memory. We are talking about cryo-etching technology.

Currently, in the production of flash memory, etching processes are used at temperatures ranging from 0 to +30 degrees Celsius, and the new technology in question implies a temperature of −70 degrees Celsius.  ;

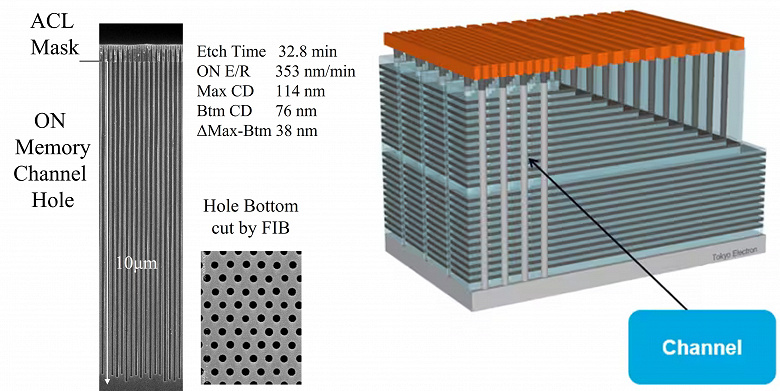

The new generation etching machine can produce 10 micron deep etching with a high aspect ratio in just 33 minutes, more than three times faster than existing tools. This achievement is not only a major technical improvement, but also significantly improves the production efficiency of 3D NAND memory, which can change the production time and output quality of 3D NAND devices.

Hynix is considering this technology to produce memory with more than 400 layers. Now manufacturers have not yet reached even 300 layers, and Samsung is the leader here.

Hynix is now testing the technology by sending wafers to the Tokyo Electron laboratory in Japan. Interestingly, Samsung also appears to be evaluating the same technology, but has brought the tools to its lab.