This material is used for 3D printing

In Russia, for the first time, a pilot industrial technology for the production of filament was developed — material used for 3D printing — made of continuous carbon fiber based on thermoplastics.

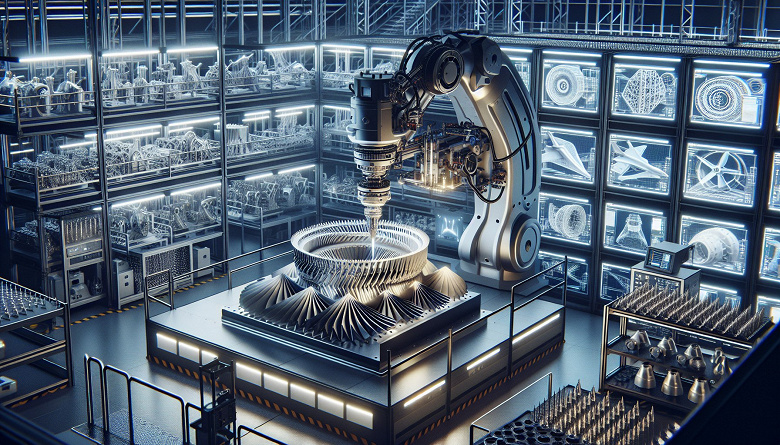

Candidate of Technical Sciences, Head of the Laboratory «Polymer Composite Materials» Advanced Engineering School «Digital Engineering» Peter the Great St. Petersburg Polytechnic University (SPbPU) Ilya Kobykhno said that the technology will be introduced into industrial production in the near future, and will be used in the rocket, space and aviation industries.

«For more than 10 years, our team has been developing technologies for impregnating carbon fibers with thermoplastic polymers from the polyaryletherketone group. It is very important for us that the results of our painstaking work will soon be introduced into industrial production. Solving the problem of producing domestic filaments from this material — this is another step towards achieving technological sovereignty for our country, — noted Kobykhno.

Carbon fiber has high strength and stiffness, but it is very light, which is an advantage of a material that is also resistant to high temperatures or chemical attack. Carbon fiber filaments can be used for 3D printing in fused deposition printers (FDM and FFF).

This material is strategic for the USA, Switzerland and China, and therefore is practically not exported. Employees of PISH SPbPU «Digital Engineering», in addition to the technology, also manufactured a laboratory installation for the production of filaments from continuous carbon fiber based on thermoplastics with a productivity of 500 m of filament per hour. This installation was also the first in Russia.

A pilot industrial line will be put into operation this summer, which will operate using this technology, and experts are already working on improving the technology and installing it with a capacity of 12,000 m/h.