This was confirmed by careful tests

Few people thought that large parts for aircraft would be printed on 3D printers, but this is already happening. A research team in Wuhan, China, has 3D printed the world's first such part for an aircraft landing gear.

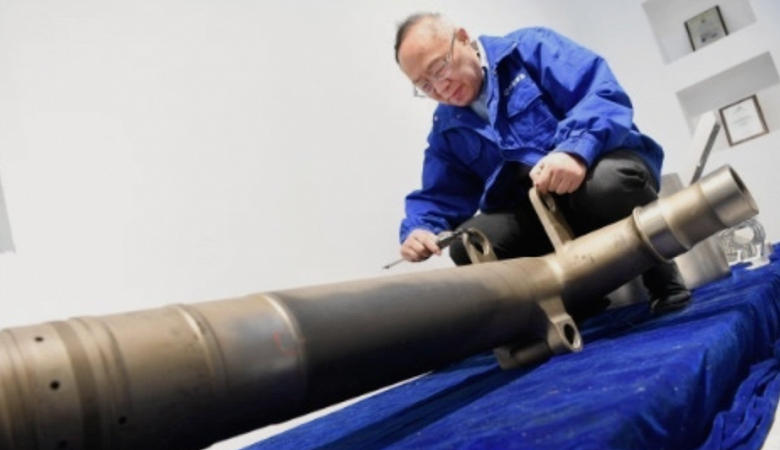

This massive T-shaped element is visually indistinguishable from its metal counterpart, which is 1.5 meters long and weighs 240 kg. It was important for engineers to overcome problems with 3D printing, which mean that parts are prone to cracking. Professor Zhang Haiou's team from Huazhong University used a new 3D printer that combines casting, forging and milling. It bridged the gap between traditional manufacturing processes.

Professor Hiou says that compared to traditional methods, material savings are 90%, resulting in significant savings and environmental benefits. Rigorous testing confirms that 3D printed parts are even stronger than traditionally manufactured components.

Currently, only a few countries can produce landing gear for large aircraft. Wuhan Tianyu Intelligent Manufacturing, the company behind the innovation, is the first to 3D print such an important part.

This innovation has the long-term potential to completely revolutionize the aircraft industry by offering a more cost-effective and environmentally friendly approach. Perhaps in the future, 3D printed airplanes won't seem as fantastic an idea as they do today.