What the Chinese taught the Belarusians

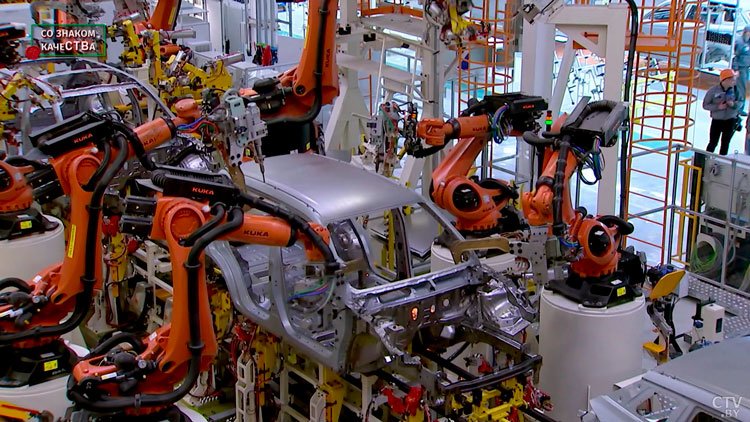

Interesting details about the work of the BelGi plant, which produces Geely cars, were published by the Belarusian publication ctv.by.

Sergei Tradchik, chief technologist of SJSC BelGee, said: “This is the first full-cycle plant in the territory of the Republic of Belarus, which includes welding, painting, assembly. Factory stroke: one car – 4 minutes. It takes 24 hours to produce a car from start to finish. And this plant is designed and based on Geely factories in China. Our specialists were trained at Chinese factories, because in our country there were no such competencies. And at that moment, upon their return to our plant, they said that we are now building, using, even better than theirs at that time. I would like to give an example from 2019-2020, when we were updating our model range, there were corresponding restrictions on movement. In fact, we did all the work involved in putting new models into production ourselves. Accordingly, with the support of Chinese colleagues remotely from China. This speaks volumes about the level of our specialists who work at the plant».

Even during the pandemic, Chinese colleagues helped carry out modernization remotely, as described by Vladimir Shavel, Deputy Director – Chief Engineer of SZAO «BelGee».

Now that all restrictions on visits have already been lifted, they come, train our workers, and give us advice. We work together, and they provide us with technical support in this regard. The mentality is different, the approaches are different, but when working together, our mentalities agreed. They are accustomed to our actions, we are accustomed to their actions. Together we achieve positive results in this work. Discipline, of course, is an international concept, but in the Celestial Empire it is ironclad in every sense. And the Chinese borrowed the formula for success from the Japanese. To get a quality product, you need to add five «s».

Vladimir Shavel

Victoria Korochkina, deputy head of the technical control and quality department of SJSC BelGee, adds: “They really have reinforced concrete discipline, a built system based on the principle of global automotive industry practice. We have implemented a lot of things. For example, Just in Time. We all know this concerns delivery times – right on time. Using shortcuts for timely provision and production of components in strictly required quantities. Jidoka – built-in quality – to eliminate the transfer of possible inconsistencies to other operations. Next – various ways of visualizing possible defects, applying the principles of the three “don’ts”: do not accept the defect, do not do it and do not transfer it to another operation. «Alone in the field is not a warrior». This Slavic proverb perfectly reflects the Chinese approach to business. The machine-building conveyor here is like a relay race. If one stumbles, the other must lend a shoulder. Result – exclusively team».

The most important stage, it seems to me, is installing the chassis, engine, suspension (because these are load-bearing parts after all), connecting the wiring so that there are no problems. We have implemented a self-control system in our workshops, that is, the employee does his job – installs some part. At the next post there is a man – shop controller, also known as keeper, – which checks the same operation that the person performed. If there are any questions about the installation or if there is some damage or defect somewhere, the keeper has the opportunity to eliminate this defect. They come out of this situation that they help each other. That is, if the workshop has done something, it fixes it itself, and helps itself. Belarusian meticulousness is added to the Chinese philosophy of hard work at this plant. Before a car sees the light of day, it will be closely examined by dozens of eyes and carefully probed by dozens of hands.

Dmitry Belkov, head of the finished product inspection bureau of SZAO «BelGee».

Previously it was reported that Belarusian batteries, tires, and glass are already being installed on Geely cars. They are preparing to begin production of plastic parts for the exterior and interior.