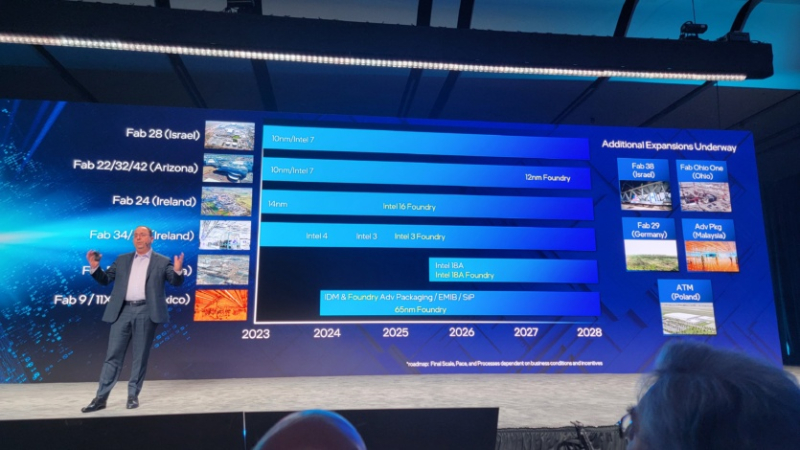

During the Intel Foundry Direct Connect event, the company announced that it plans to launch production/development of the Intel 10A node (1nm equivalent) in late 2027. However, production based on the 14A node (1.4 nm) is planned for 2026. The company is also working on creating fully autonomous AI factories in the future.

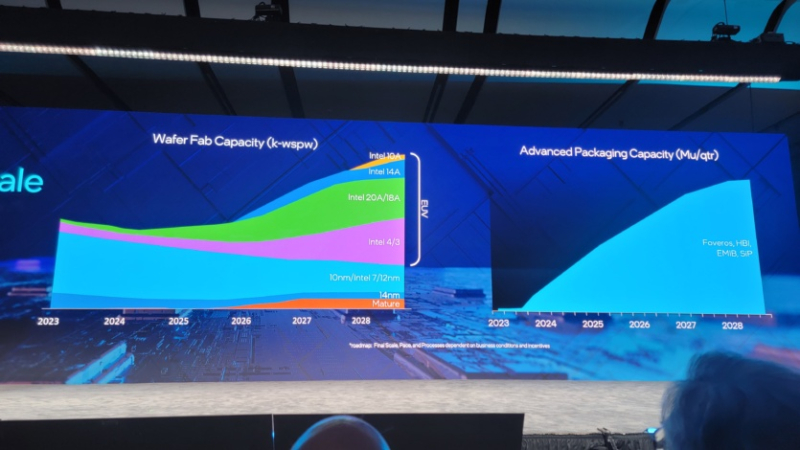

On the slide you can see what share of silicon wafers the company plans to use for the manufacture of chips based on various production processes.

In its previous announcements, Intel did not specify a start date for its upcoming 14A node, but has now announced that it will begin production in 2026. More importantly, Intel will begin production/development of its yet-unannounced 10A node in late 2027. The A suffix in Intel's node names stands for angstrom (a unit of length equal to 10-¹⁰ m, or one ten-millionth of a millimeter), and 10 angstroms becomes 1 nm, making it the company's first 1-nm class node.

Intel didn't provide any details about the 10A node, but said it should provide double-digit power/performance improvements. Improvement over node 14A is expected to be 14-15%.

Intel plans to aggressively expand its capacity to produce Foveros, EMIB, SIP and HBI packaging. This will ensure a constant supply of advanced processors with complex packaging, including HBM.

Frontend course. A frontend developer can easily create side pages for a website or web add-on. Therefore, after the course, you will become a sought-after lawyer in the sphere that is developing. Information about the course

At the same time, the company intends to expand its activities. In addition to existing manufacturing capacity, Intel plans to invest $100 billion in expansion and new manufacturing sites over the next 5 years. Geographically distributed manufacturing facilities will allow Intel to have global redundancy in its operations while also offering its customers the ability to leverage a supply chain located entirely in America.

It is also noted that the company relies heavily on automation of its production facilities. Intel now plans to use artificial intelligence in all segments of its manufacturing pipeline, from capacity planning and forecasting to improving yield and actual production operations. The time frame for such changes is not specified, but they should affect every aspect of the company's activities in the future. This includes the introduction of AI “Cobots” (collaborative robots that can work alongside humans) and widespread robotic automation in the manufacturing process.